Universal® Clamp Applications

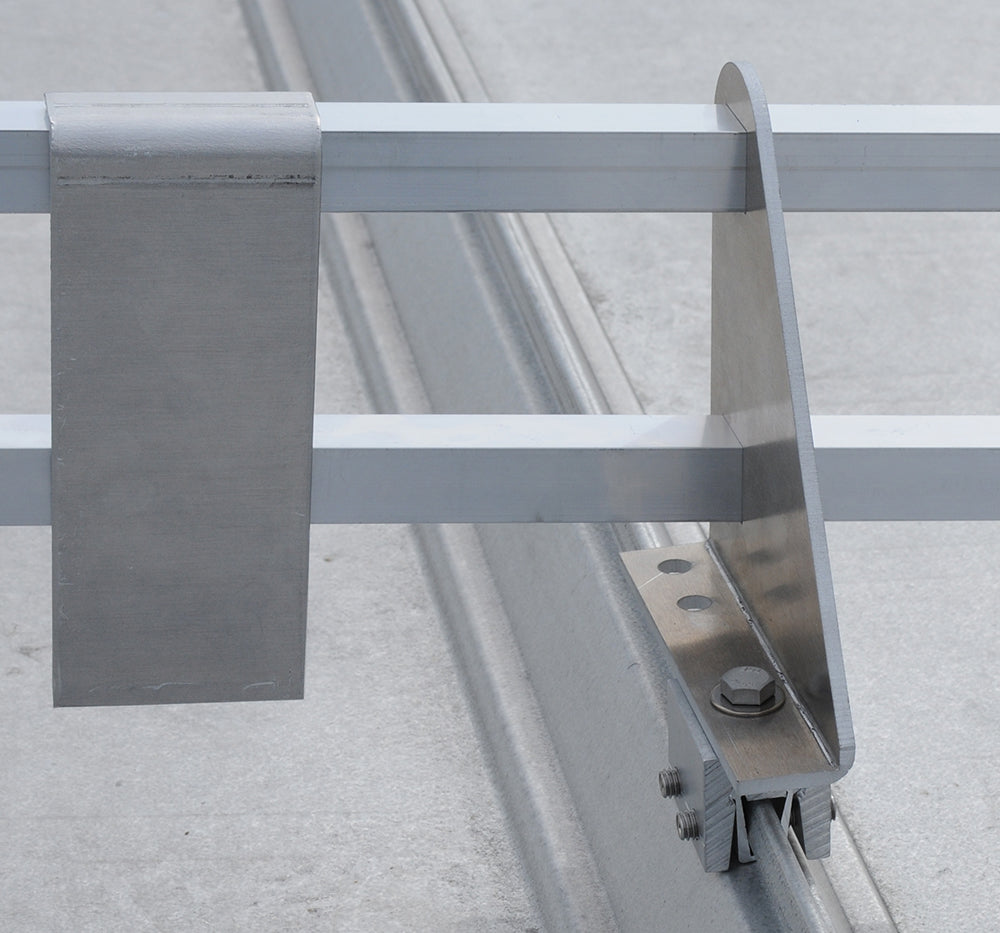

The Universal® clamp uses innovative locking hammers on one or both sides of the clamp to engage with a standing seam, creating even pressure along the length of the clamp. Other manufacturers engage the seam with two set screws, putting all the pressure on one point, which can cause holes, tears, and other damage to the roof, voiding roof warranties and creating leaks. Universal® Clamps are constructed using the highest quality aluminum bodies and hammers with stainless-steel set screws, reducing the risk of rust, deformation, or deterioration. While our four standard hammer types accommodate most seam profiles, custom hammers can be engineered for project-specific applications.

Universal® Clamps can be shipped pre-assembled with hammers, set screws, and mounting bolts already in place for efficient clamp installation, or shipped with all the hardware sent in separately labeled bags.

The only tool required to install a Universal® clamp is a 3/16″ hex bit. The clamp is placed onto the standing seam at the attachment point and the set screws are tightened on each side to lock the hammers. It is recommended that 16-20 ft/lb. of torque be applied to the set screws to achieve the maximum holding force.

Universal® Clamps are laboratory certified and have achieved exceptional parallel and perpendicular test results.

Photovoltaic Rack Mounting

The Universal® clamp was originally designed to mount photovoltaic panel racking systems to a standing seam metal roof. The racking can either be mounted to the top or side of the clamp via a 3/8-3/16″ threaded bolt. Mounting holes can be customized, pending engineering approval, making the Universal® clamp even more versatile.

Conduit Mounting

Universal®Clamps are the perfect solution for providing a secure connection for conduits, pipes and other building mechanical systems to standing seam metal roofs. Commonly used with slotted metal framing struts, 3/8-3/16″ threaded bolts can be mounted to the top or side of the clamp. The mounting holes can be customized, pending engineering approval.

Snow Guard Mounting

-

Universal® Clamps are the ideal solution when installing a snow guard system to a standing seam metal roof. A snow guard protection system is designed to allow small amounts of ice and snow to fall, minimizing damage to gutters, shrubbery, and, most importantly, people located below the roof. The patented Universal® Clamps Heated Snow Guard melts snow and ice to further minimize the risk of falling ice.

-

Snow guards typically come in two different styles: a “pipe” or a “pad”. A “pipe” style, which is usually the most effective, utilizes vertical mounts attached at the seams with a series of horizontal pipes running from mount to mount. A “pad” style system utilizes a piece of metal or plastic located on each seam. Universal® Clamps are an effective solution to both of these types of snow guards. The snow guards can either be mounted to the top or side of the clamp via a 3/8-3/16″ threaded bolt or the holes can be customized, pending engineering approval.

Sign Mounting

Because the clamp features multiple mounting options, many different types of signs and sign mounting systems can be attached to metal roofs and sidings. Signposts and legs can attach to the top or side of the Universal®clamp with 3/8-3/16″ threaded bolts or the holes can be customized, pending engineering approval. The strength and durability of the clamp allows for peace of mind during severe weather. The balanced load created by the clamps’ patented hammer design keeps the sign from tilting overtime.